Want to place stirrups but the options are greyed out?

This is one of the most common question we get having to do with masonry beam design so if this is something you are stuck on, know that you are not the first! We’ll first break down the reasons for this issue and then quickly outline what you can do about it.

First of all, this is not a bug in the code. This issue is a product of the way the 2004 S304 standard limits stirrup spacing. It has since been addressed in the 2014 edition and MASS Versions 3.0 and newer will allow two course designs with stirrups.

When does this happen?

This issue is specific to beams designs where:

- The beam is 2 courses high or less, and

- The beam is failing in shear design for having a shear resistance that is too low

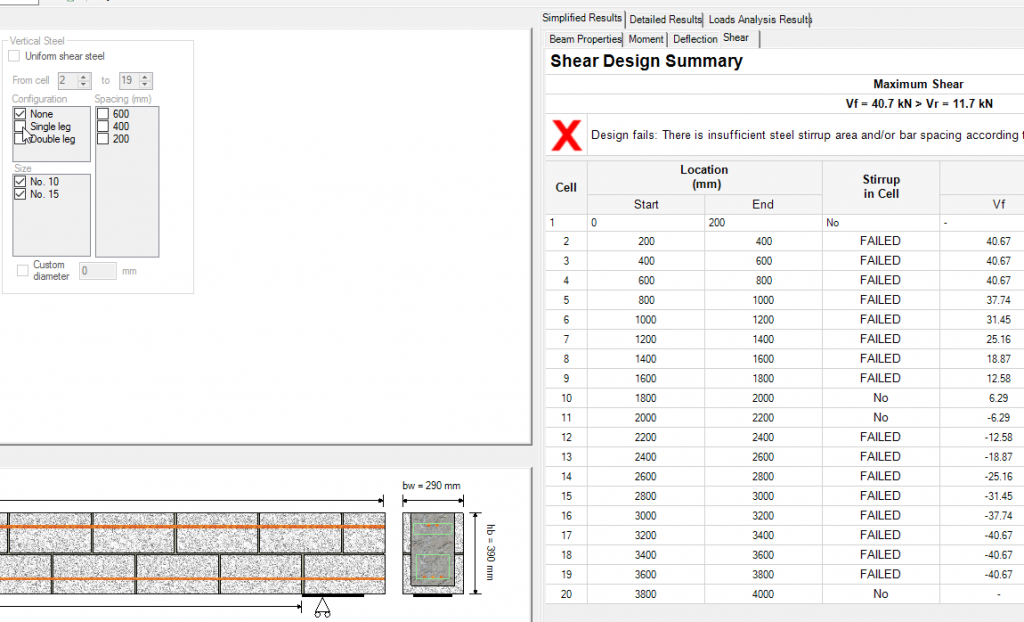

You can see in the screenshot below that only the “none” option is selected for stirrup placement and if you try and click the single or double leg selections, nothing happens because the whole input area is greyed out or “disabled”.

The fix seems obvious, right? Just add some stirrups to boost my shear capacity! This is where we run into problems.

Why MASS won’t let you just add stirrups to your beam

The error message you are seeing reads: “Design fails: There is insufficient steel stirrup area and/or bar spacing according to CSA S304.1-04: 11.3.4.7.1,2 and/or 11.3.4.8”.

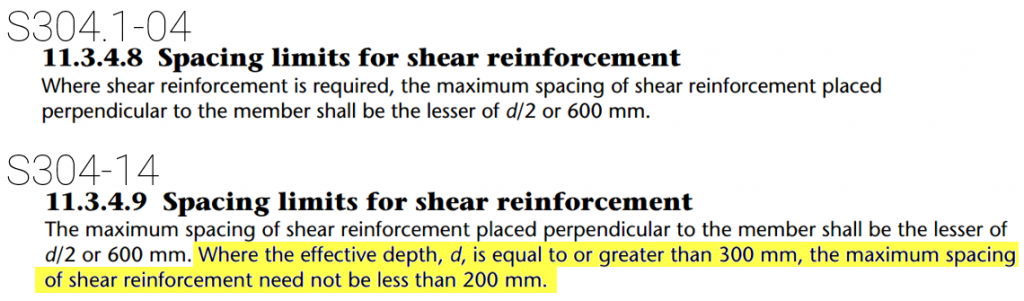

For reference, 11.3.4.7.1 and 11.3.4.7.2 each refer to stirrup placement and minimum area requirements. The issue we are running into comes from 11.3.4.8 which covers “Spacing limits for shear reinforcement”.

The issue here and the reason MASS will not let you place stirrups in your beam is that clause 11.3.4.8 is specifying a maximum spacing of d/2 which for 2 course beams is less than 200mm. MASS recognizes this and greys out the option to even place stirrups because the modular nature of masonry restricts you to multiples of 200mm (or the space between the centre of adjacent cells in concrete block construction).

Since you cannot physically place stirrups closer than 200mm within a masonry beam, MASS disable this option.

As you can see, there is no way to place stirrups any closer than one per cell. For those curious, these beams were built for university research supported by CMDC. You can read more about that here.

What you can do to get a successful design

You have a couple of options to get your design to pass. You can always send your MASS project file over to us in an email and we can walk through these options together over the phone as well. To do this, visit our contact page to get in touch.

1. Re-examine your loads

Oftentimes when going through a design, there are assumptions that are made along the way that can have a big impact on the final design. In the case of load distribution, are all of the loads being carried straight down to the beam or can arching be assumed as outlined on page 305 of our textbook? Did you manually add the self-weight of the beam in your dead load? If so, you might be double counting if you have the self-weight option selected in the loads window. Are there other loads applied that might not actually be resisted by the beam? All of these can mean the difference between a beam design passing and failing in shear design based on the loads applied.

2. Model an additional course of masonry within your beam

Many masonry beams are supporting more masonry above them so why not take advantage of this by considering a third course to be part of your beam? The real world difference could mean as little as simply grouting an additional course but the key difference is that the increase in height and in turn, d (depth of tension steel from compression face), moves the d/2 spacing restriction to being greater than 200mm. This might not be possible if the clear span is very small since the additional course might bump you into deep beam territory but for most designed masonry beams, adding the third course to your design does the trick!

3. Think about using a high lintel unit

If you can’t get your d/2 value below 200mm, you can approach the problem from the other direction and remove the 200mm restriction by changing to a high lintel beam design. High lintel beams have a continuous grouted area that can fit any reinforcement configuration. They can even be modeled in MASS for those of you who are feeling more ambitious! Give us a call if you are interested and we’ll be happy to walk you through it.

Click here to see high lintel masonry construction in action!

A high lintel beam contains a soldier course of block directly above the opening. High lintel units look like tall U-shaped blocks and can be ordered from the unit supplier.

The nice thing about a high lintel design is that you don’t have to worry about your stirrups lining up with the webs of the concrete blocks. You gain the versatility of being able to drop in any configuration of reinforcement (including using any stirrup spacing) and then simply drop it in and grout around it.

Here you can see several high lintel beams used in one project.

4. Consider using a stronger masonry unit

No, this does not mean you also need to increase your grout strength (See note 4 of Table 4 within the S304 masonry standard for reassurance). Using a unit with a higher f’m value increases the shear strength of the masonry itself, possibly giving you enough resistance as to no longer require stirrups in your beam. This is not always practical and is only effective if the failing masonry shear resistance is close to the required factored shear force.

One more thing…

Seeing as this whole issue is born not from a software bug but the way the CSA S304 standard was written, MASS Versions 3.0 and newer will not have this issue. CMDC currently maintains an active role in shaping and developing masonry standards and as a result, the 2014 edition of the S304 standard includes an addition to the “problem” clause, 11.3.4.8, which now includes a minimum value of 200mm for the maximum spacing of stirrups.

It is for this reason that the issue you are dealing with now will no longer be a problem when you start designing with the 2014 S304 standard.

Still have questions? Feel free to call or send us an email! (Including your MASS file is very helpful)