Dillon, Patrick B.1

Staff Engineer II, WDP & Associates Consulting Engineers, Inc., 335 Greenbrier Dr., Suite 205, Charlottesville, VA, 22901, USA, pdillon@wdpa.com

ABSTRACT

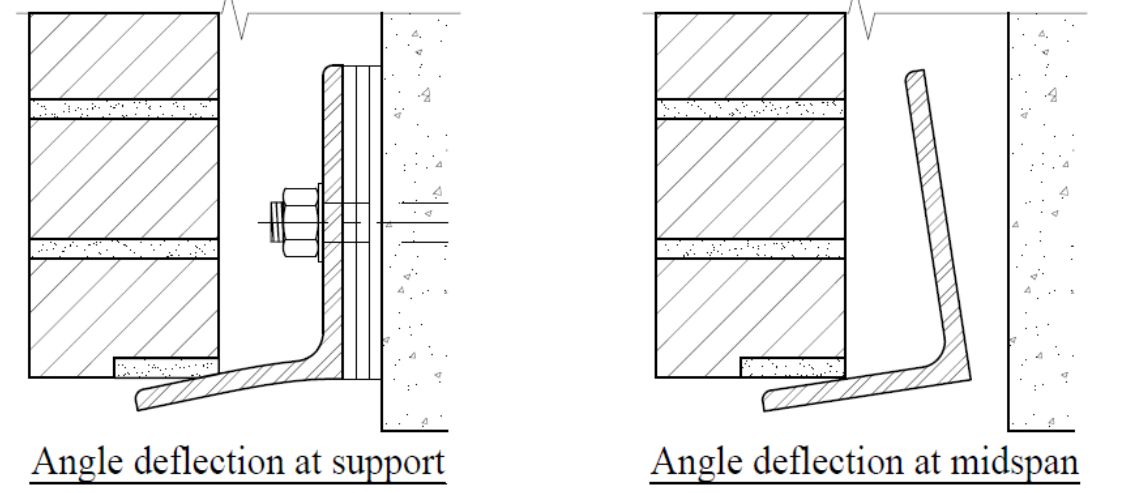

Energy code requirements for buildings have increasingly become more stringent in the amount of insulation required in the building envelope system. In order to satisfy the continuous insulation requirement, designers are opting to place the insulation in the cavity, which necessitates a larger width. The recently published TMS 402-16 includes an increase of the maximum prescribed cavity depth requirement for masonry veneers. The typical cavity width in US construction will certainly increase as the TMS 402-16 requirements are legally adopted by local jurisdictions. Now appears to be an ideal time to rejuvenate the topic of shelf angle design. Relatively little has been published regarding the design of shelf angles for supporting masonry veneers. Shelf angle design is not as simple and intuitive as it might appear at first glance. Design simplifications often produce overly conservative results that unnecessarily increase the size and cost of the shelf angle and its installation. Common design assumptions are discussed and compared to previous studies. A comparison of analysis approaches from the literature confirmed that most approaches produce results that are extremely over-conservative. A new design model is proposed which more accurately accounts for the interaction between the masonry panel and the shelf angle. Results from analysis of a case study are presented and compared for multiple shelf angle design models. The analysis results show that the deflections and load distribution on a shelf angle are less than what is typically assumed in design. The proposed model shows that shelf angle deflections are smaller than what is determined from the other models. Use of the proposed model has the potential to reduce the size and installation costs of shelf angles.

085