1 Assistant Professor, ir., Department of Masonry Structures, Eindhoven University of Technology, Eindhoven, the Netherlands, g.bertram@bwk.tue.nl

2 Professor, ir.-arch., Department of Masonry Structures, Eindhoven University of Technology, Eindhoven, the Netherlands, d.r.w.martens@bwk.tue.nl

ABSTRACT

One aspect of our investigation into the spacing of movement joints in masonry walls involved the short and long term deformation of mortar embedded in masonry. In this research the influence of hardening conditions on the physical and mechanical properties of thin layer mortar for Calcium Silicate Elements were studied, with a focus on the shrinkage by hardening.

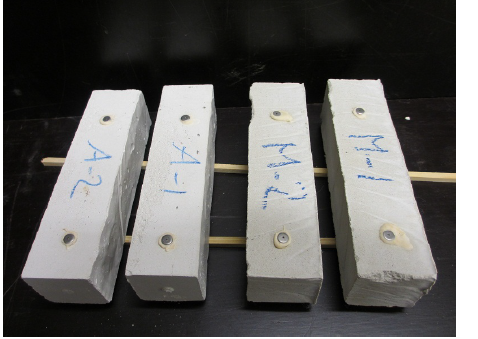

Mortar prisms made in steel moulds (according to European Standards) under seven different moisture conditions during hardening were compared to mortar prisms made in a mould made of Calcium Silicate bricks to evaluate the influence of water suction. During the test period the weight, deformation and strength of the specimens were determined. The results were also compared with similar tests on masonry mortar for clay bricks and thin layer mortar for clay bricks and concrete bricks.

In the experimental research a significant influence of the hardening conditions on the final material characteristics of the mortar was found. In some cases material properties were reduced by a factor 2. The values of the strength and strain of mortar hardened in steel moulds do not give correct results for calculating the spacing of movement joints in Calcium Silicate masonry.

KEYWORDS: mortar, hardening conditions, movement joints, crack control

265.pdf