M. SHOKRY RASHWAN AND SIMAAN M. ABOURIZK

ABSTRACT

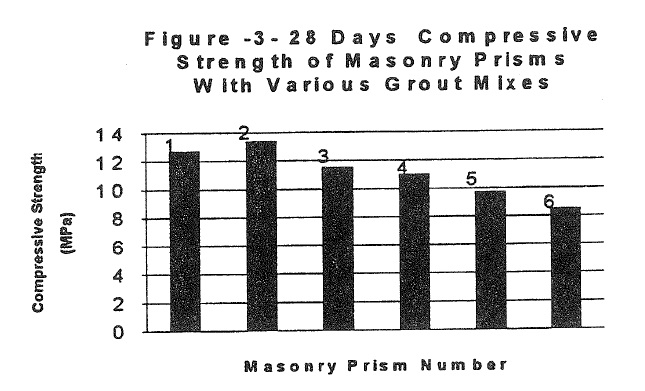

An extensive study was conducted to evaluate the technical, economical and environmental viability of using grout made of recycled concrete blocks and clay brick. The recycled material was obtained from waste generated on construction sites. The waste was then processed into aggregate on the same site, using a compact processor developed for this purpose. Recycled material was used, in different proportions, to make concrete suitable for grouting masonry block walls. The technical investigation has focused on studying the properties of original material (i.e., before recycling), the recycled aggregates and the grout made of such material. Test results have shown that recycled aggregates possess higher absorption capacity and lower density than natural aggregates. Depending on the cement: aggregate ratio, grout samples made of such aggregate had compressive strength that complies with code requirements. Masonry prisms filled with grout made with recycled aggregates have also attained compressive strength values within the code requirements. Thermal conductivity coefficients of samples made with recycled aggregate were much lower than those obtained for control mixes. The economic investigation has focused on comparing the cost of on-site recycling process with the ever-increasing cost of disposing of such waste. The environmental study, on the other hand, was a simple task due to the immense benefits that can be gained from such a process. The paper presents the results of part of such investigations and the recommendations of how to maximize the benefits gained from on-site construction and demolition masonry waste recycling process.

F-32