C.S. Barbosa1 and J.B. Hanai2

1MSc. Structural Engineering, PhD Student, Department of Structural Engineering, University of Sao Paulo, School of Engineering at Sao Carlos, Brazil, E-Mail: claudius@sc.usp.br

2Professor of Civil Engineering, Department of Structural Engineering, University of Sao Paulo, School of Engineering at Sao Carlos, Brazil, E-Mail: jbhanai@sc.usp.br

ABSTRACT

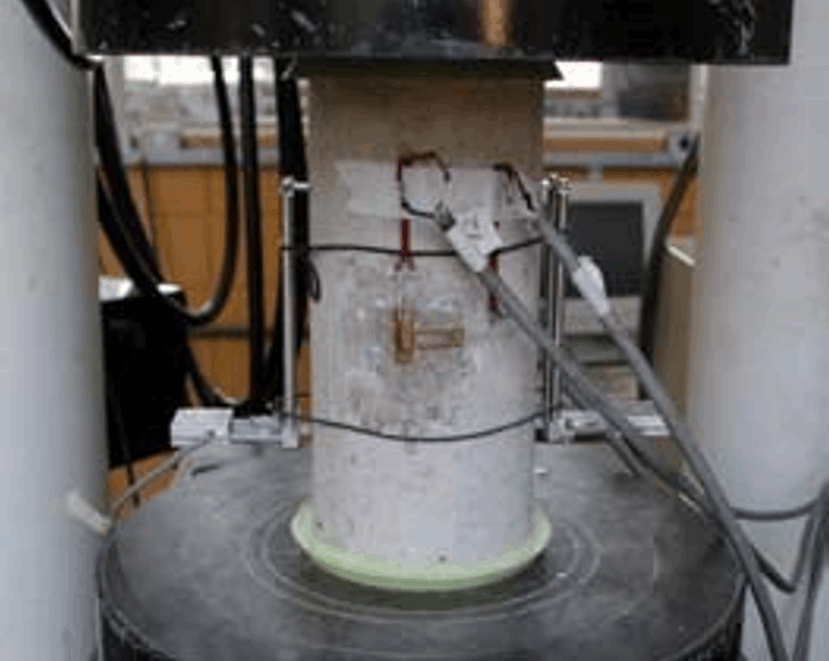

This paper deals with the correlations between the mechanical properties of hollow blocks and the concrete utilized in their production. Hollow blocks and test samples of different types and sizes were simultaneously cast with concrete having the same plastic consistency. Plastic consistency of concrete was used to assure the same characteristics in the blocks and test samples. Three different concrete strengths were defined to correlate the mechanical properties in compression and tension tests. In addition, two and three blocks high prisms without typical mortar joints were tested in axial compression. In these cases, the prisms were constructed with full blocks mortared together with a thin epoxy resin layer in the bed joints. Axial compression tests on blocks and prisms showed non-uniform stress and strain distribution in the mean cross section of these specimens. Even in the case of two and three blocks high prisms, a non-uniform distribution of strains was clearly observed. The influence of the platen effect was observed. It was also observed that geometry and slenderness of the tested specimens also influence the compressive strength correlation of cylindrical samples, blocks and prisms. Even minimizing the mortar joint effect on prisms, the relationship between prism and sample compressive strength reduced when increasing the height of the tested element.

KEYWORDS: Hollow concrete blocks, strength, deformability, properties of constituent materials.

2b-4