Hagel, Mark1; Isfeld, Andrea2 and Rizaee, Samira3

1 Executive Director, Alberta Masonry Council, Suite# 205, 2725 – 12 Street NE, Calgary, AB, Canada, markhagel@albertamasonrycouncil.ca

2 Postdoctoral Scholar, Department of Civil Engineering, Schulich School of Engineering, 2500 University Drive NW, AB, Canada, acisfeld@ucalgary.ca

3 PhD. Student, Department of Civil Engineering, Schulich School of Engineering, 2500 University Drive NW, AB, Canada, srizaee@ucalgary.ca

ABSTRACT

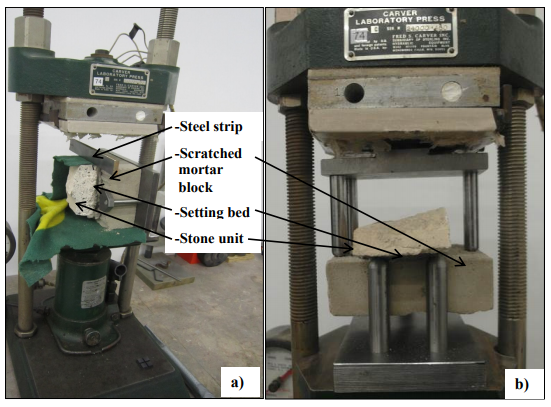

Thin masonry veneers individually secured by mortar adhesion (adhered masonry veneers) have become increasingly popular in the North American construction industry. As the height of the adhered masonry veneer increases, however, the reliance on mortar bond to attach the thin masonry cladding to the support structure also increases and the greater the risk of damage to property or injury if that bond fails. This paper explores the results of testing the shear and tensile bond strength of adhered manufactured stone veneer units when Type N, Type S, polymer modified stone veneer mortars, and improved modified dry-set cement (thinset) mortars were used. The results of the testing illustrated that two types of failures can occur, bond failure of the setting bed to substrate and bond failure of setting bed to the back of the stone unit. The testing also demonstrated that traditional Type N and Type S mortars had difficulty achieving the 0.35 MPa (50 psi) shear bond strength required by ASTM C482, ASTM C1780 and ASTM C1670 when the ASTM C482 test was modified to better replicate field installation of adhered masonry veneers. Only the thinset mortars consistently exceed the 0.35 MPa requirement.

114