Zeyad H. R. Hakam1, Ahmad A. Hamid2, Mohamed Elgaaly3

- Senior Project Controls Engineer, Bechtel Power Corporation, 5275 Westview Drive, Frederick, Maryland, 21703, USA; Email: zhakam@bechtel.com

- Professor, Civil & Architectural Engineering Department, Drexel University, 3141 Chestnut Street, Philadelphia, Pennsylvania, 19104, USA; Email: hamidaa@drexel.edu

- Professor, Civil & Architectural Engineering Department, Drexel University, 3141 Chestnut Street, Philadelphia, Pennsylvania, 19104, USA; Email: elgaalym@drexel.edu

ABSTRACT

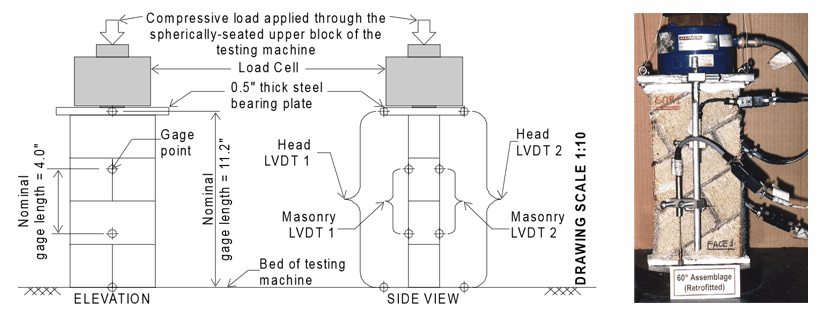

Many existing masonry-infilled steel frame buildings do not meet today’s seismic design standards. Cracking, spalling, and collapse of infill masonry walls which, in turn, lead to substantial structural damage and even collapse of the bounding steel frame have been reported in areas of moderate to high seismicity. A research program, sponsored by the National Science Foundation, was initiated at Drexel University in order to investigate the effectiveness of using glass fiber reinforced plastic (GFRP) laminates to retrofit hollow concrete masonry infilled structural steel frames and to demonstrate the ability of the proposed technique in improving the seismic performance and the strength and deformation characteristics of the infilled frame system. Selected results of Phase I of this investigation, which focused on the use of GFRP laminates to retrofit hollow masonry assemblages subjected to on-axis and off-axis in-plane compressive loads, are presented in this paper. The laminates altered the failure modes of the masonry assemblages and reduced the variability and anisotropic nature of the masonry. Only marginal strength increase was observed for assemblages which exhibited compression failure modes, while significant increases were observed for those which failed due to shear and/or mortar joint slip.

Key words: concrete masonry, infill walls, infilled steel frames, composite laminates, on/off-axis compression tests, unreinforced masonry, retrofit technique

frp03