Eixenberger, Joseph1 and Fonseca, S. Fernando2

1 PhD Candidate, Department of Civil and Environmental Engineering, Brigham Young University, 368 Clyde Building Provo, UT 84602, USA, eixenb86@byu.net

2 Professor, Department of Civil and Environmental Engineering, Brigham Young University, 368 Clyde Building Provo, UT 84602, USA, fonseca@byu.edu

ABSTRACT

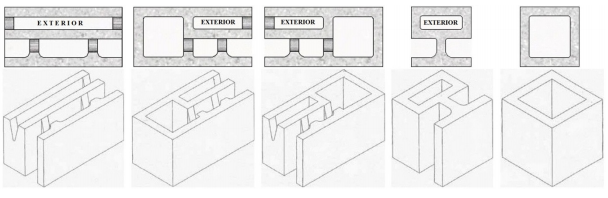

Dry-stack masonry systems are built without mortar between the units. Dry stacking reduces cost of labor and variability in construction and minimizes the required skilled labor. There are two subcategories of dry-stack systems: interlocked and surface bonded. Interlocking systems use the block geometry to connect one block to another and surface bonded systems uses a surface layer, usually cementitious in nature, to connect the blocks together. Depending on the load demand, dry-stack systems can be unreinforced (grouted or ungrouted) or reinforced and grouted. This

article describes an experimental study where a dry-stack surface bonded wall system was tested for its out-of-plane flexural capacity. Six walls were constructed and tested. The walls were assembled with concrete masonry units, and, after stacking the blocks to form the walls, a glass fiber reinforced cementitious surface coat was applied to the walls. All walls were 2.44 meters by 2.44 meters and made with 200 mm thick units. Two walls were unreinforced and ungrouted, two walls were reinforced and grouted at 1.22 m on center, and two walls were reinforced and grouted at 0.61 m on center. A structural steel frame was assembled to support the walls and the walls were pinned at the bottom and top. The lateral load was applied to the face of the walls through a whiffletree system, which had two steel channels placed at third points (approximately 0.81 m and at 1.62 m from the bottom) along the length of the walls. The ultimate load on the walls were 4.8 and 5.7 kN for the unreinforced walls; 43.7 and 48.8 kN for the walls reinforced at 1.22 m on center, and 60.0, and 68.0 kN for the walls reinforced at 0.61 m. The results from the tests were compared and determined to be comparable to the design load calculated using the TMS 402 masonry code provisions.

031