1 Ph.D. Technical Manager. Building Construction, Chemical Lime Company. Henderson. Nevada U.S.A. 89015. formerly Research Officer, National Research Council of Canada. Institute for Research in Construction. Ottawa. Canada.

2 Proffessor. Department of Civil Engineering, Carleton University Ottawa. Ontario. Canada; and President. Suter Consultants Inc. Consulting Engineers Ottawa. Ontario.

3 P.Eng.. Senior Conservation Engineer. Architectural and Engineering Services for Environment Canada, Public Works and Government Services Canada. Ottawa. Canada.

4 Ph.D. P.Eng.. Institute for Research in Construction, National Research Council Canada. Ottawa. Canada

ABSTRACT

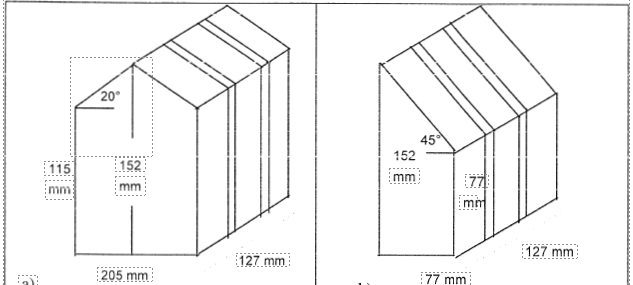

Horizontal surfaces of masonry courses such as capstones. plinth stones and window sills are subjected to severe exposure conditions as they frequently project beyond the plane of the building and act as drip surfaces. The design and construction of durable vertical mortar joints therefore, presents major challenges to any masonry restoration project. Vertical joints were examined in the laboratory as part of a larger mortar research program investigating performance criteria for restoration mortars to be used on the Parliamentary buildings in Ottawa. Canada. Three configurations were tested. representing cap stones. plinth stones and window sills. The joints were filled with mortar only, or also included a foam backer rod with sealant. Mortar mixes with masonry cement & type N hydrated lime. Portland cement & type S lime. and Portland cement & calcitic (high-calcium) lime putty were used. Testing focused on frost durability using a unidirectional freeze-thaw cabinet.

9468.pdf