A.T. Vermeltfoort

Associated Professor, Section Structural Masonry, Department of architecture, building and planning, Eindhoven University of Technology, P.O. Box 513, 5600 MB, Eindhoven, The Netherlands, a.t.vermeltfoort@tue.nl

ABSTRACT

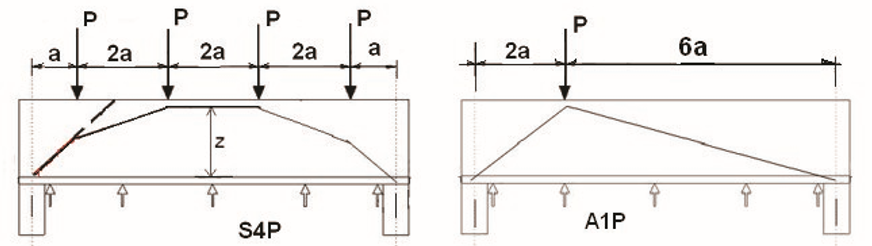

This paper describes research into the behaviour of so-called “composite lintels” i.e. load bearing masonry in combination with prefabricated concrete lintels. Eighteen identical walls were loaded in plane to rupture. Nine layers of stretcher bond masonry, 562.5 mm in height, were built on prefab concrete lintels (60×100 mm2) with a span of 2800 mm. The effects of two types of supports and two types of loading on the mechanical behaviour of in plane loaded composite lintels were studied. Roller supports were simulated by suspending steel blocks from the roof beam of the test frame. A support condition, often used in practice, was simulated by a layer of felt on a brick. Two series of six walls were symmetrically loaded at four points. A third series of six walls were asymmetrically loaded at one point. The mean failure shear load for the four point loading condition was Vfail = 31 kN. For the one point condition it was Vfail = 24.4 kN. On average, the ultimate load (Fult) was 15% higher than the failure load (Ffail). Supported on rollers, three walls failed in the constant moment area (mid span). The fifteen other walls failed in the maximum shear load area near the supports. The height of the compression zone at mid span depended on the support condition and was largest for the felt support condition, where horizontal movement of the lintel was restrained. The support condition (rollers or felt) had a negligible effect on the load bearing capacity.

KEYWORDS: Composite lintel, support, shear, strength variation, load bearing masonry

B8-2