1 Executive Director, Canadian Masonry Research Institute, Edmonton, Alberta

2 Professor of Civil Engineering, University of Alberta, Edmonton, Alberta

INTRODUCTION

Differential movements between the two wythes of a cavity wall and/or between a brick veneer and it’s backup system have been the topic of many engineering reports, particularly dealing with failures and failure investigations.

Because of the existence of information in the form of test data and reports documenting expansion of burned clay units after manufacturing, many of the failures of brick cladding systems have been attributed to this observed expansion. It is thus commonly believed that the expansion of burned clay units is the main contributing factor to the observed distress in masonry cladding systems where the expansion of the clay unit was not accommodated by means of a horizontal, and vertical control ( expansion) joints.

The available literature mainly from the masonry industry, and in particular the burned clay industry, is primarily based on measurements and experimental work on units or small walls constructed and monitored in laboratories. These conditions do not represent the exposure and weathering of units and wall assemblies of actual structures.

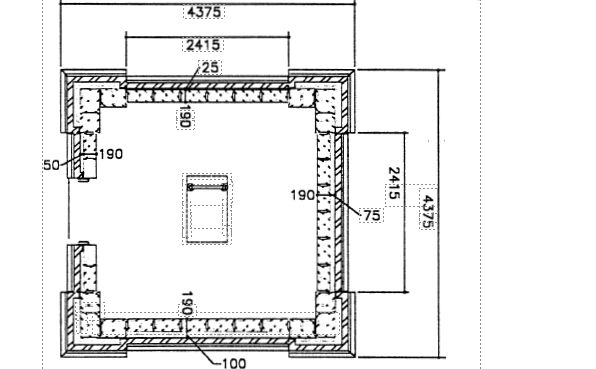

In order to expand the database to field conditions, it was decided to carry out an investigation over a long period of time in an actual permanent structure built for the sole purpose of establishing the magnitude of shrinkage, expansion, temperature related movements and differential movements in cavity walls.

0238.pdf