1 School of Civil Engineering, University of Leeds, LS2 9JT, United Kingdom cnhvm@leeds.ac.uk

2 School of Civil Engineering, University of Leeds, LS2 9JT, United Kingdom j.p.forth@leeds.ac.uk

ABSTRACT

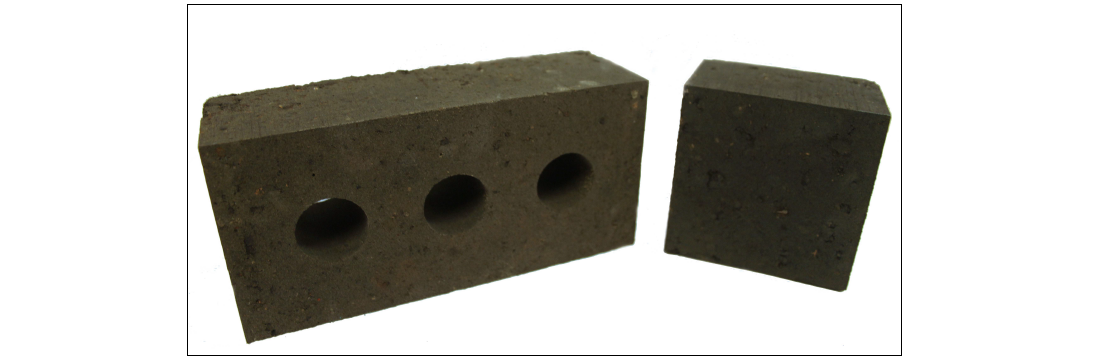

This paper presents an investigation into the development of a novel glycerol bound masonry unit. The research is motivated by the desire to enhance the sustainability, both nationally and globally, of masonry units. The production of the units from entirely waste materials is possible because a blend of waste glycerol and waste cooking oil is used as the binder; the aggregates include incinerator bottom ash (IBA) and pulverised fuel ash (PFA). The compressive strength and water absorption properties of the units were measured to assess their performance in relation to masonry products found in the UK. These properties are good indicators of overall performance. Results from the study demonstrate that the units can be produced with properties that are at least equivalent to those of currently used masonry units.

KEYWORDS: masonry, glycerol, cooking oil, oxidation, hardening, strength

457.pdf