John Harrison B.Sc. B.Ec. F.C.P.A.

Managing Director, TecEco Pty. Ltd., Australia

ABSTRACT

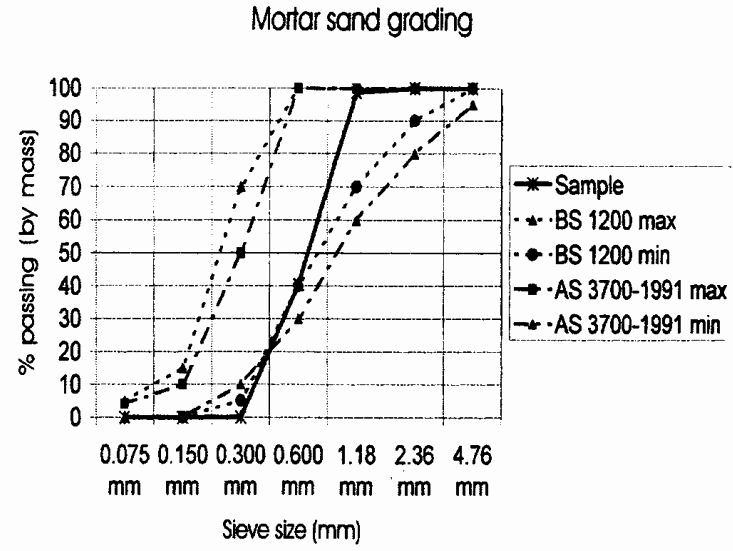

In spite of the increasing availability of mortar-less products, mortar has traditionally held walling units together and is still the choice of many builders. Blended lime – Portland cement (PC) mortars are becoming more fashionable and hydraulic, partially hydraulic or carbonating lime mortars are certainly preferred for restorative work. The requirements for proper carbonation when carbonating lime or the new eco-cement magnesian mortars are used are however poorly understood, especially in the English speaking world. This paper compares carbonating and hydraulic mortars and discusses the chemistry of the strength giving reactions involved as well as the impact of physical factors such as aggregate size, grading and moisture. The role of aggregates for proper carbonation is considered from a theoretical point of view and in terms of best practice from the past. The paper concludes that sands suitable for hydraulic mortars are not suitable for carbonating mortars and vice-versa and points out deficiencies in the current standards and codes of practice that do not recognize this. A new direction is suggested that combines the best practice from the past with that of the present.

KEYWORDS: Aggregates, mortars, lime, eco-cement, sand, grading, standards, carbonation

1a-3