Samira Rizaee, Mark Hagel and Nigel Shrive

Samira Rizaee, Ph.D., Civil Engineering Department, University of Calgary, 2500 University Drive NW, Calgary, AB, Canada, srizaee@ucalgary.ca

Mark Hagel, Engineering Director, Alberta Masonry Council, Suite 166, 3-11 Bellerose Drive, St. Albert, AB T8N 5C9, AB, Canada, markhagel@albertamasonrycouncil.ca

Nigel Shrive, Professor, Civil Engineering Department, University of Calgary, 2500 University Drive NW, Calgary, AB, Canada, ngshrive@ucalgary.ca

ABSTRACT

Adhered thin manufactured veneer (ATMV) has been used extensively as the exterior layer in building envelopes over the past 15 years. The application of ATMV has never been regulated, so

traditional mortar types were preferred as the adhering agent due to their lower initial cost compared to polymer modified mortars (thinset). However, there have been numerous bond

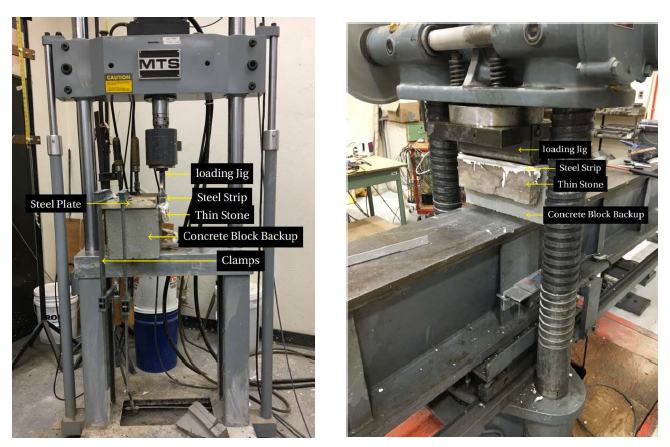

failures in ATMVs when traditional mortars have been used. Thus, more knowledge is needed and consequently regulations should be implemented for safe application of ATMV. In this study, the bond strength of thin stones and thin brick to concrete block backing using polymer modified or Type S mortar was studied. Then the effects of age (7, 14 and 28 days and more) and testing temperature (20 and -40°C) were investigated. The first three stones did not differ significantly in their shear bond strength with polymer modified mortar, reaching a minimum of 2.1 MPa strength. This suggests that the shear strength with these stones is more influenced by the mortar than the stone units or that the stone types are very similar. When investigating the influence of mortar type, the maximum average shear bond strength using Type S mortar was 0.31 MPa indicating difficulty achieving the minimum bond strength of 0.35 MPa required by ASTM C1670. In

contrast, the minimum strength achieved using polymer modified was 1.2 MPa, about 4 times greater than the strength achieved using Type S mortar. Statistical analysis of the test results shows that there are no significant differences in the strength with respect to age or temperature at testing. This suggests that the bond between the thin units and the adhering mortar gains most of its strength in the first 7 days and very cold temperature does not result in weaker bond strength.

KEYWORDS: adhered manufactured thin stone, polymer modified mortar, shear bond strength, thin stone veneer