1 Executive Director, Alberta Masonry Council, Calgary, AB, Canada, T4C 0H8 markhagel@albertamasonrycoucil.ca

2 Professor, Schulich school of Engineering, Department of Civil Engineering, Calgary, AB, Canada, sllissel@ucalgary.ca

3 Professor and Killam Chair, Schulich school of Engineering, Department of Civil Engineering, Calgary, AB, Canada, ngshrive@ucalgary.ca

4 Senior Technical Services Engineer, Canadian Concrete Masonry Producers Assoc., Toronto, Canada, bbstek@telus.net

ABSTRACT

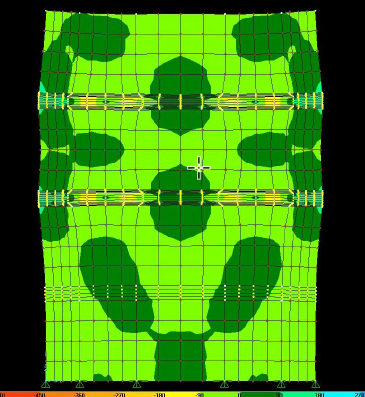

A simplified finite element model was developed in SAP2000 to explore the stress generated in the mortar surrounding a corrugated strip tie by the volume increase in the tie as it corrodes. The typical tensile and shear strength of masonry is taken to be 0.3 and 0.65 MPa [1] for design purposes, and it was deemed likely that the mortar would crack if this value was exceeded. Shell elements were used to model the brick, mortar and tie of a four brick tall prism based on the brick prism specimens used in experimental work. The first finite element model had a 22 gauge 13/16” x 6” corrugated strip tie embedded in the middle bed joint while the second finite element model had a 4.76 mm diameter wire tie embedded in the middle bed joint The finite element models demonstrated that expansion forces due to corrosion products can cause micro-cracking of the mortar surrounding the embedded tie when the volume reaches a critical amount. The amount of volume expansion due to corrosion on the very thin corrugated strip ties estimated in the field on 40 year old tie samples was approximately 110 to 120% at the advanced stages of steel corrosion. The finite element models demonstrated this level of expansion could induce stresses that may cause cracking of the mortar surrounding the tie.

KEYWORDS: corrosion, brick ties, finite element model

111.pdf