Amy Huynh, Yuxiang Chen, Carlos Cruz-Noguez and Mark Hagel

Amy Huynh, MSc Student, Department of Civil and Environmental Engineering, University of Alberta, 116 St & 85 Ave, Edmonton, AB, Canada, ahuynh@ualberta.ca

Yuxiang Chen, Assistant Professor, Department of Civil and Environmental Engineering, University of Alberta, 116 St & 85 Ave, Edmonton, AB, Canada, yuxiang.chen@ualberta.ca

Carlos Cruz-Noguez, Assistant Professor, Department of Civil and Environmental Engineering, University of Alberta, 116 St & 85 Ave, Edmonton, AB, Canada, cruznogu@ualberta.ca

Mark Hagel, Engineering Director, Alberta Masonry Council, Suite 205, 2725 – 12 Street NE, Calgary, AB, Canada, markhagel@albertamasonrycouncil.ca

ABSTRACT

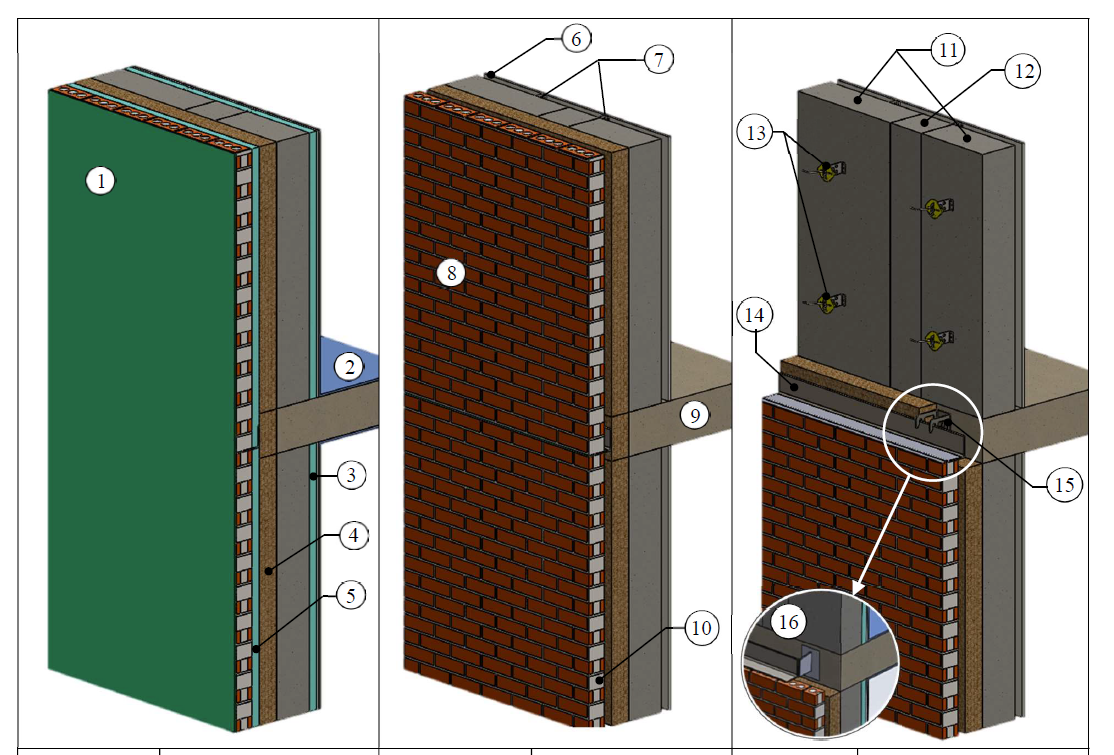

New energy codes for buildings in Canada require energy losses associated with thermal bridging to be accounted for by designers. In masonry systems, most of the energy losses from thermal bridging are due to structural penetrations at floor levels located at shelf angles. This is because most of the shelf angle systems currently used in practice are made of steel, which is a highly

conductive material. New technologies, such as plastic polymer, have been proposed to reduce the bridging losses, but there are few studies on the effect of the various technologies. 3D thermal

modeling provides accurate predictions of thermal performance when addressing masonry thermal bridging. This study used 3D thermal modeling to investigate the influence of various parameters (e.g. stand-off shelf angle connector geometry, thermal properties, spacing of stand-off connectors, insulation thickness). The results of the 3D modeling were used to help determine a numerical relationship that can be applied to calculating thermal bridging effects.

KEYWORDS: heat transfer, masonry wall systems, R-value estimation, shelf angles, thermal bridging, thermal modeling