Al-Jaberi, Zuhair1; Myers, John2 and ElGawady, Mohammed3

1 Ph.D. Candidate, Department of Civil, Architectural &Environmental Engineering, Missouri University of Science and Technology, 1401 North Pine Street, Rolla, MO 65409, USA, zkayc7@mst.edu

2 Professor, Department of Civil, Architectural &Environmental Engineering, Missouri University of Science and Technology, 1401 North Pine Street, Rolla, MO 65409, USA, jmyers@mst.edu

3 Associate Professor, Department of Civil, Architectural &Environmental Engineering, Missouri University of Science and Technology, 1401 North Pine Street, Rolla, MO 65409, USA, elgawadym@mst.edu

ABSTRACT

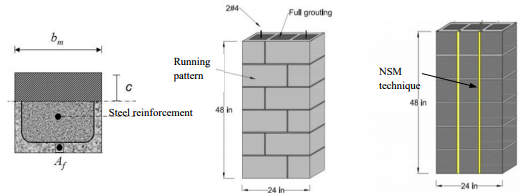

Fiber reinforced polymer (FRP) composite have been used effectively to strengthen reinforced masonry and concrete structures. However, the performance of FRP composite strengthening systems is still of great concern especially when it’s exposed to harsh environmental conditions. In this study, an effort was made to investigate the flexural behavior of reinforced masonry walls

strengthened with near surface mounted (NSM) FRP bars and exposed to different weathering actions. The walls performance was investigated by exposing the specimens to 350 different

environmental cycles through a computer-controlled environmental chamber. These cycles are proposed to simulate 20 years of the typical in-situ weather conditions of the Central US. Seven reinforced masonry walls were built for this study. An identical reinforced masonry walls in its unstrengthened form are used as control specimens. Constant reinforcement ratio (ρ) for mild

steel was used. Two sets of three specimens strengthened using NSM with different types of FRP bars (glass and carbon) and carbon strip were tested. The first set was tested after at least 28 days

as a curing period of laboratory conditions, while the other set was tested after 72 days of exposure to combined environmental conditions. The walls tested in four-point bending under

cyclic load with loading rate 1.27 mm/min. In term of flexural capacity, the specimen strengthened with CFRP bar was affected by weathering condition more than the specimens strengthened with CFRP strip or GFRP bar. Different modes of failure occurred in the strengthened reinforced walls, including a punching shear failure through the concrete block, as well as debonding of FRP reinforcement from the masonry substrate.

010